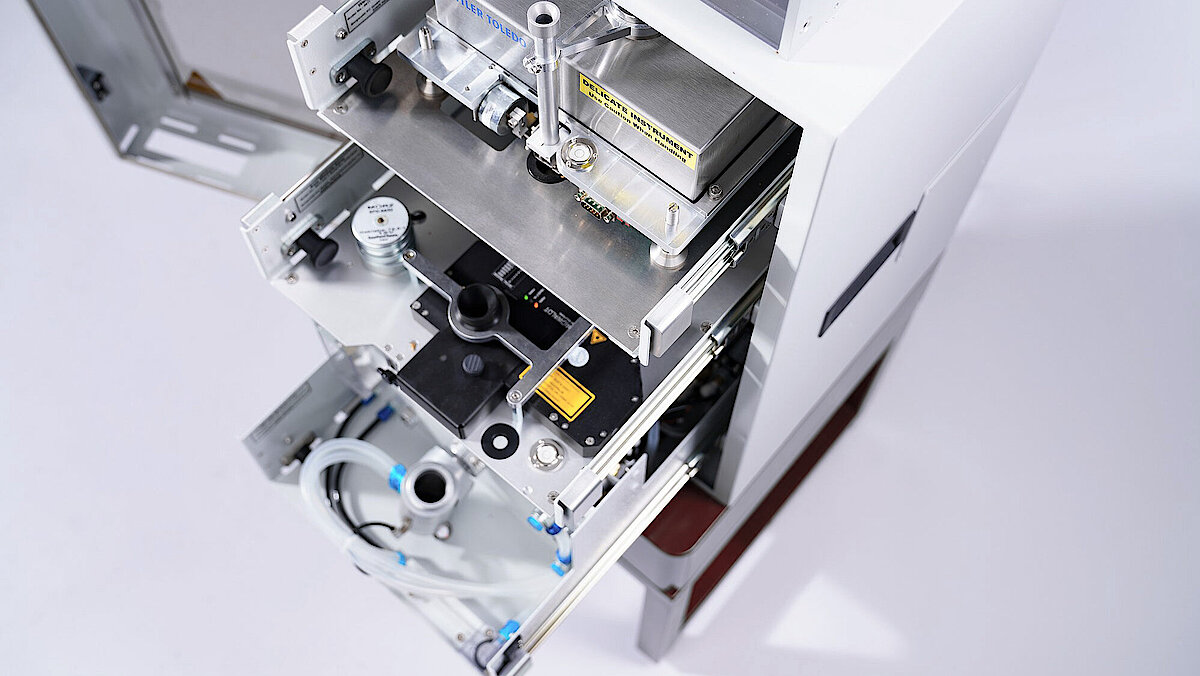

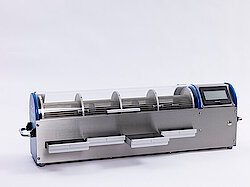

HAUNI SMI - DIAMETER or CIRCUMFERENCE is designed to measure the diameter or circumference of cigarettes, filter rods and small cigars. For this, the laser head scans the product to produce the mean diameter of the sample.

Features:

- displays the diameter or the circumference

- complies with ISO 2971

- SMI modular stations are stackable and easy to use

- compact and robust design makes them ideal for production environments

- readings are displayed speedily in 2 to 3 seconds after a measurement

- the SMI modules are connected to a PC

- 4 SMI modules can be connected to one PC

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/8/csm_Air_leak_detector_Sodiseal_Ko__rber_15eb42f644.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/e/csm_game_changer_sensors_2_ec12eb0ae3.jpg)